PLASTIC

Solutions & Services

For the Hromatka Group, plastics distribution means more than just getting high-quality plastics from A to B on time. We offer pre- and post-delivery services related to polymers that you will rarely find in one place. And above all, we also offer something that is essential today: fast solutions. Thanks to our local positioning, we offer immediate on-site assistance throughout Europe through analysis and problem solving, even directly during ongoing production.

Project development

Planning and consulting as the basis for solid products

Every product starts with a plan. Once the initial ideas have been collected and the requirements specified, the time has come to contact us: Our plastics technicians will work with you to evaluate which materials are best suited to your project. It is important for us to speak a common language. And by that we don't just mean the national language, but also the needs and requirements of the individual industry segments. segments. Because automotive and medical are often closer to each other than we would like, but the demands on plastics in the industries are completely different, we have experts and materials that are in daily use in the industry and use their expertise to offer fast and precise solutions.

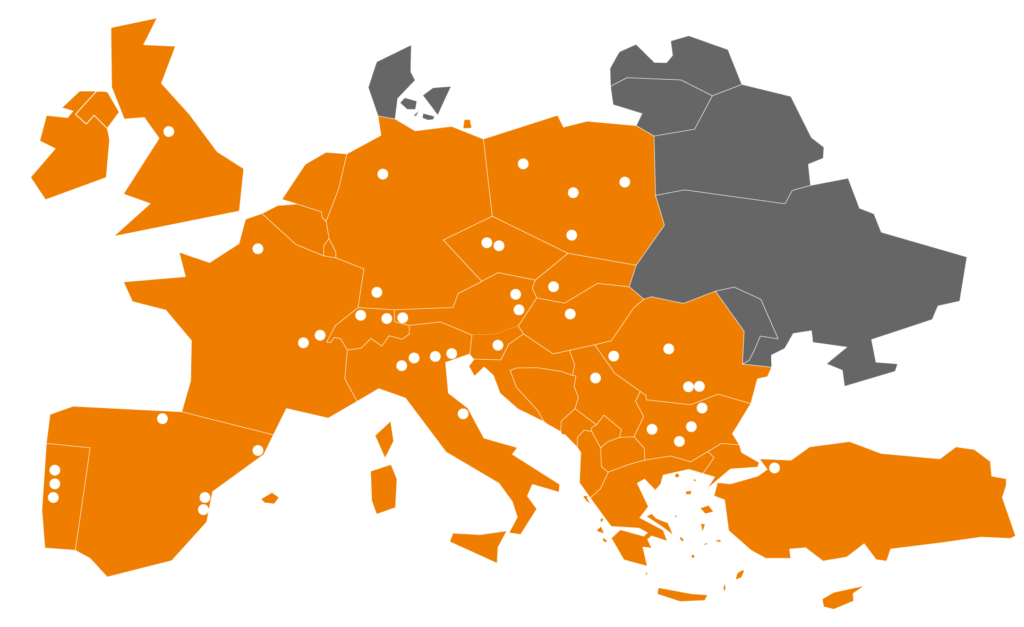

In the joint development process, we not only ensure that every requirement is met, but also provide suggestions on how processes and the final product can be further optimized based on the material and tool. Our 150 local, industry-specific application engineers and technical sales consultants in 25 European countries in 25 European countries have access to well over 5000 materials in stock from more than 100 manufacturers. If the request is so specific that it cannot be fulfilled despite the enormous selection of standard materials, we develop and produce customized compounds to measure.

There for you: from project development to after-sales support

Engineering

Concept, design and simulation

Our engineers also help to make products better and better beyond the selection of materials. When it comes to optimizing components, Impetus Plastics Engineering, which is part of the group of companies, is on hand with help and advice. In our highly specialized engineering company for product development in the plastics sector, engineers from the fields of plastics technology and design apply systematic development methods and modern CAx techniques.

With many years of experience from over 2000 successful projects and innovative ideas, which have been realized with well-known manufacturers, it is possible to design an optimal product in form and functionality within a defined time and financial framework in the area of product development and streamlining.

OEMs usually have their production sites spread across the continent. But wherever you are, we are always close by and provide you with identical material quality. Everywhere in Europe.

A Europe-wide

warehouse and delivery network

Others call it supply chain management. We call it reliable, uninterrupted supply throughout Europe.

All locally operating companies in the Hromatka Group operate their own warehouses. However, they maintain a lively exchange of know-how, materials and technology. This ensures that OEMs who place their orders across national borders the same material quality is available without restriction. Regardless of the production location at which they operate.

Our warehouse network

The optimum component helps to reduce costs and increase performance. We help to design it.

Security through planning -

our local logistics services

Having a plan does not mean that everything runs according to it. We know that plans change.

Since we know our customers' requirements, we calculate the expected goods consumption in advance, which we take into account in our own warehousing. If a customer also uses our safety stock the material is stored in advance and is available without restriction for exclusive call-off at any time. Should there be a change of plan on the customer side, we are already prepared for this.

Combined with our own fleet of vehicles, this ensures independence in transport planning and the reliable availability of delivery slots is guaranteed.

Spontaneous additional requirements are only a reason for you to be happy: because we have your material in stock.

Compounds

made to measure

We offer customized material solutions under the "SAX Polymers" brand. In our own compounding facility, we prepare almost all technical thermoplastics according to customer requirements

We manufacture polymers on a total of over 15 production lines according to requirements agreed with the customer. Our database currently contains over 6000 formulations with a wide range of design and material specifications. Those with a recycled content in particular are currently experiencing significant growth. We welcome this current trend towards a sustainable economy and therefore process almost all post-consumer and post-industrial waste, as well as food waste, into new, high-quality raw materials. Our plastic crystallizer and special material developments from our laboratories provide the basis for this.

The Swiss site specializes in amorphous plastics and the recycling of PET. Vienna mainly produces semi-crystalline compounds.

What both have in common is customer-specific mixing - from very small quantities to batches of several thousand tons. The following modifiers are used:

Visual adjustment with colors and effects

Modification with fillers and reinforcing materials such as glass beads, mineral fillers, glass and carbon fibers

Emphasis on special properties through the addition of tribological additives, flow aids, stabilizers, impact modifiers, UV and flame protection systems

Improvement of environmental properties through recyclates, wood and oyster shells

Together with customers and universities, but also independently, we develop new compounds ready for series production. Our most recent development is granulates made from food waste.

The laboratories associated with compounding are well equipped with over 50 testing devices to continuously evaluate the quality of our products using physical and chemical tests, but also to analyze any phenomena that occur and initiate appropriate measures.

As part of our quality management we carry out material and processing checks using comprehensive standardized test and inspection methods, analyse our own materials and those reported by customers and ensure the consistent quality of all raw materials from the outset and across national borders.

If defects are detected by processors, immediate analysis enables an immediate response so that the customer's production does not come to a standstill.

If your application requires customized material, you've come to the right place. Regardless of the quantity.

The closed loop

begins and ends with us

In terms of sustainability, more and more companies are striving for a closed material cycle. For us, this begins with original raw materials. But for us, it also ends responsibly: we take back processed materials in the form of production waste and reprocess them as part of post-industry recycling. For the benefit of the environment and the budget, the thermoplastics cycle with us.

Your material remains your material. From the first to the last grain of granulate. Instead of expensive disposal, we reprocess your production waste so that you can continue to use it without any losses.

We are the

HromatkaGroup

Strong partners. Strong performance